×

SparkFun will be closed on Tuesday, December 24th, and Wednesday, December 25th, in observance of the Christmas holiday. Any orders qualifying for same day shipping placed after 2:00 p.m. (MST) on Monday, December 23rd, will be processed on Thursday, December 26th, when we return to regular business hours. Wishing you a safe and happy holiday from all of us at SparkFun!

Please note - we will not be available for Local Pick up orders from December 24th-December 27th. If you place an order for Local Pick-Up we will have those ready on Monday, December 30th.

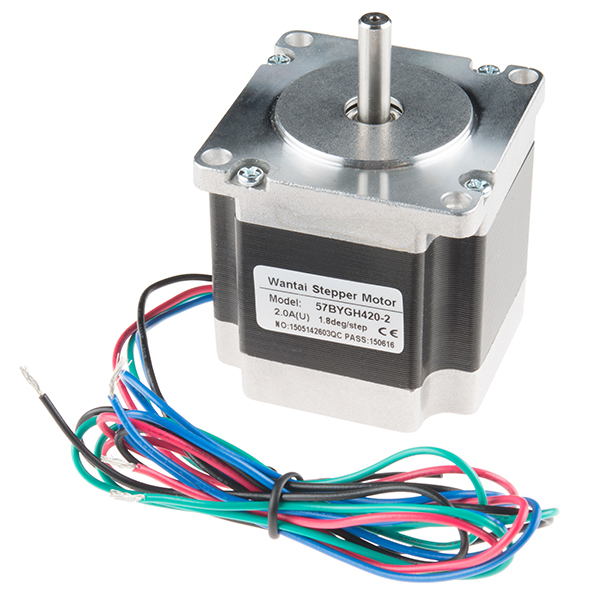

Stepper Motor - 125 oz.in (200 steps/rev, 600mm Wire)

Stepper motors are great motors for position control. They can be found in desktop printers, plotters, 3d printers, CNC milling machines, and anything else requiring precise position control. Steppers are a special segment of brushless motors. They are purposely built for high-holding torque. This high-holding torque gives the user the ability to incrementally “step” to the next position. This results in a simple positioning system that doesn’t require an encoder. This makes stepper motor controllers very simple to build and use.

These stepper motors, in particular, are used with the Shapoko CNC machine and offer 125 oz.in of torque and 200 steps per revolution. Additionally, each motor has been equipped with extra long 600mm AWG22 wires, making them ideal for CNC applications.

Note: This is a Bipolar stepper.

- 2-Phase

- Steps per Revolution: 200

- Step Angle: 1.8°

- Voltage: 3.2V

- Current: 2.0A/Phase

- Resistance: 1.6± 10% Ω/Phase

- Inductance: 5.5± 20% mH/Phase

- Recommended Holding Torque: 125 oz.in

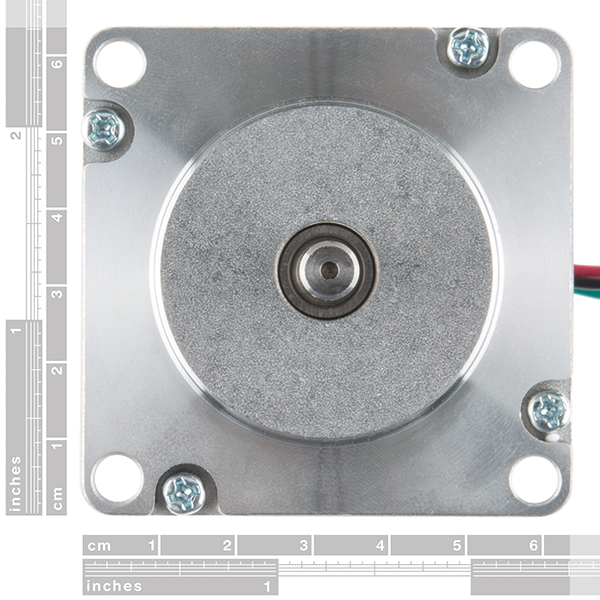

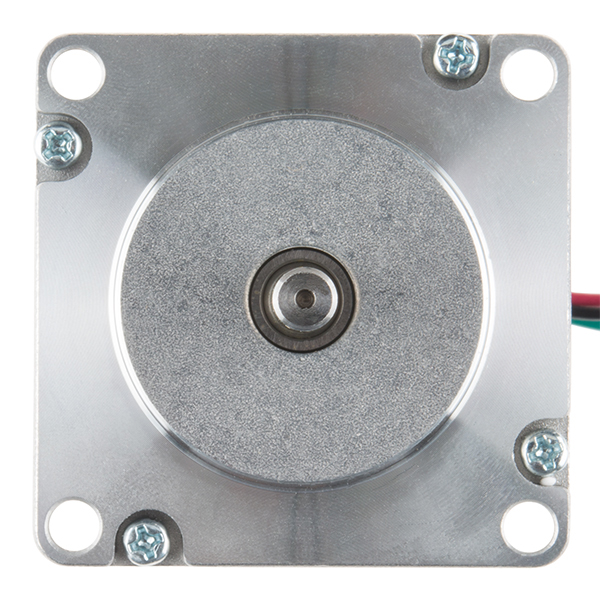

- NEMA 23 Form Factor

- 600mm Long AWG22 Wire

Stepper Motor - 125 oz.in (200 steps/rev, 600mm Wire) Product Help and Resources

Shapeoko Coaster Project

November 20, 2015

A step-by-step guide to cutting and engraving a coaster with the Shapeoko.

Shapeoko Assembly Guide

April 21, 2016

A guide for attaching the Stepoko Add-on kit to a Shapeoko Mechanical kit.

Core Skill: Robotics

This skill concerns mechanical and robotics knowledge. You may need to know how mechanical parts interact, how motors work, or how to use motor drivers and controllers.

Skill Level: Experienced - Your experiences should include working with stepper motors and feedback system. You may need to understand how encoders and more complex control systems work.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Competent - You will be required to reference a datasheet or schematic to know how to use a component. Your knowledge of a datasheet will only require basic features like power requirements, pinouts, or communications type. Also, you may need a power supply that?s greater than 12V or more than 1A worth of current.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

5 out of 5

Based on 4 ratings:

Excellent

It's working perfectly

I am very happy to owned product like this motor

Strong and precise!

This stepper motor is a great buy. Very sturdy/solid build in a compact design. Works as described and I have no complaints about it.

Works fine

Ran it on 5 volts with Arduino motor shield. Nice and quiet and lots of torque!

Very powerful!

I picked this one out not really knowing much about stepper motors, but I went for it thinking that it had the highest torque of any of the motors carried by SparkFun. I was not let down! I can't even stop it from rotating when holding it with both hands; maybe that's normal of stepper motors, but I was surprised at how strong it is. The one tricky thing is that the shaft is totally smooth, so attaching something might be a little tricky (though again, maybe this is normal).

(Also, on another note, this thing is quite heavy — and I did get my bag double-checked by the TSA agents when I was flying with it in my carry-on; haha)

-------------------- Tech Support Tips/Troubleshooting/Common Issues --------------------

NEMA 23 Mounting Holes

To clarify, the 125 oz.in Stepper Motor uses the NEMA 23 mounting holes. The motor size of this stepper motor is slightly smaller than what you would expect for a NEMA 23 motor size width and length. Try looking at the datasheet for more information about this motor’s dimensions.

Good Morning

What is the max supply voltage for this motor?

Could I use 12V or 24V?

And what is the current for power supply I could use?

Thank you

Found a torque curve datasheet for this motor.

http://www.ht-motor.com/en/02/57BYGH.pdf

It't for a different brand but same model, and several others within the series.

At 600 pulses per second torque is about 0.83 Nm and at 2100 pps about 0.72 Nm

Thanks for the resource, when you say RPM I believe you're actually referring to PPS. With 200 steps per revolution 600PPS actually corresponds to 180RPM, and 2100PPS corresponds to 630RPM

I'm glad you spotted that! Thanks! I completely missed the PPS rather than RPM on the data sheet, so used to working with RPM torque curves. I'll have to edit my post. :D

I would like to fine tune the autodriver board (BOB-13752) to account for the BEMF of this motor . Does anyone know the electrical constant of this particular motor (Ke)? There is a method for measuring it in STMicroelectronics application note AN4144 (page 14) relating to the L6470 IC. It would be a great value add for sparkfun to put a validated number on the web site under their specs (HINT).

Contest: I own J&L Distilling Company 10 minutes down the road from your headquarters. Anyone from sparkfun that gets me that electrical constant (this week) will get their name in a drawing for a free bottle of our tasty booze. It only takes an oscilloscope and the motor. I probably could have measured it in the time it took me write this but isn't a contest and free booze more fun? I love the whole idea of your company. Great products, great creativity, (a little pricy BUT worth it). Rock on!

Cheers,

Seth

sjohnson@jldistilling.com

How can I connect this drive shaft to something without welding tools?

Look for couplers online. "Stepper motor couplers" should do the trick. Most motor shafts will not be completely circular but have a little portion that's flat. Couplers are cylinders designed to slot into that shaft, with a hole at the other end to connect it to another shaft of you choosing. If my description doesn't make sense, check it out online, here's an example of one -http://www.newegg.com/Product/Product.aspx?Item=9SIA3XT3V76533&nm_mc=KNC-GoogleMKP-PC&cm_mmc=KNC-GoogleMKP-PC--pla--Tools+-+Electrician+Tools-_-9SIA3XT3V76533&gclid=CP7s9_6O4s0CFciFfgod4ZoK6g&gclsrc=aw.ds

Thanks for the link, but this motor shaft is actually completely circular.. I'm not sure why the manufacturer would make it this way, but I'm thinking I might have to drill a small hole so that I can use a set screw or something.

what drive that i can use it with this motor? and what the power supply?

Can I use the "Big Easy Driver" to control this stepper motor? ( https://www.sparkfun.com/products/12859 )

I was just looking at this product, saw it said it was unipolar, saw Pokey's comment then refreshed the page and the Wiki link and wording was changed to Bipolar. Nice!

Wouldn't this be a bipolar stepper since it has only four leads?

Totally right, looks like it was just left over from the "previous version." Thanks for the heads up!